Service Offering

Magnus Pousette, CEO VOEE Services LLC.

Three game changing value streams

- Proven and efficient methodology to step-change culture, and implement a new strategy for maintenance driving safety, quality, and reliability.

- A sound and intuitive process establishing solid preventive maintenance plans, an RCA routine, and trained cross functional OEE improvement teams in year One.

- Improved maintenance, effective planning and high energy procurement together with our Bad Cost Identification and Elimination program drives cost down.

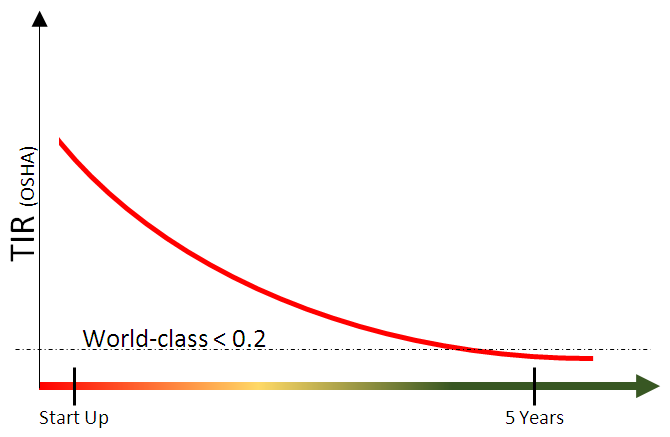

Safety Performance

- Regardless of $-value, right thing to do

- Culture change

- Reactive → Proactive

- Happening → Reliability

- Cut corners → Quality

- Order/discipline → 5S

- Individual → Team

- Top down walk the talk

- Near miss focus

- Preventive Safety Actions

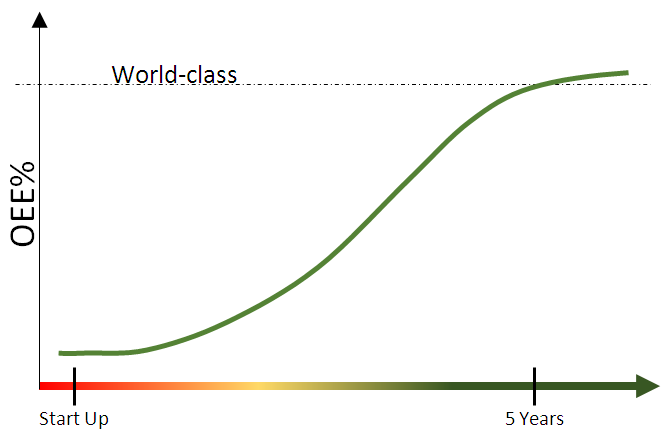

Equipment Effectiveness

- Increased capacity, always big value

- Unit cost reduction

- Higher reliability/redundancy;

- Cash from tighter logistics

- Improved on time delivery

- Take out a shift/less overtime

- Consolidate production lines/plants

- Platform to drive lean

- Market flexibility

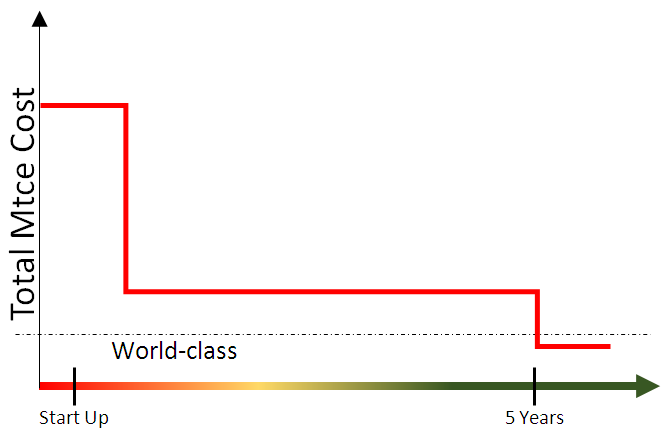

Bad Cost Elimination®

- Best maintenance practices → less intervention, less overtime, less material

- Planning drives efficiency, and enables best in class procurement

- Sharp and specialized procurement of contractors and material

- Day one change, then ongoing Bad Cost Identification and Elimination continues improvement program

- Fixed price (incl. present G&A)

- Flexibility